OUR PRODUCTS

BIOCHAR

Biochar is a highly stable, long lasting, high carbon material, recognized by the Intergovernmental Panel on Climate Change (IPCC - Paris) as a negative emissions technology (NETs) which can significantly reduce atmospheric carbon.

Currently biochar is used mainly in agriculture as a soil enhancer to increase food production. Continued development of biochar uses include its application into building materials and bio-plastics, concrete and road making, all offering long term carbon sequestration.

To assist with decarbonization of the steel making process, biochar is currently being trialled to accelerate the production of green steel.

Seata is a foundation member of Australian New Zealand Biochar Industry Group (ANZBIG) https://anzbig.org

CARBON SEQUESTRATION

Another of Seata’s benefits is the ability to sequester carbon in the form of Biochar, reducing the amount of CO2 that is re-emitted to the atmosphere.

This capability forms best practice within the renewable energy and environmental sectors and enables the users of our technology to engage and participate within the various global carbon trading markets. This also drives global outcomes in line with net zero ambitions.

SYNGAS

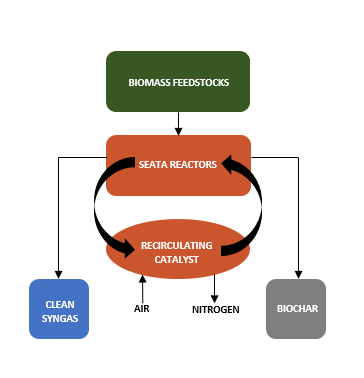

Seata’s technology produces a ready to use, clean syngas. This syngas is not diluted with nitrogen, has a very high calorific value and can be stored economically either within a gas holder/bladder or as a compressed gas. The stored energy allows for on demand generation of electricity, effectively acting as a bio-battery.

Syngas can be processed into many valuable derivative products, as detailed in the attached chart.

HYDROGEN

Q. What’s better than green hydrogen?

A. Carbon negative hydrogen

Already described as the fuel of the future and considered vital for combatting climate change, Seata produced hydrogen has carbon sequestration built-in, in the form of biochar.

FUELS

A variety of fuels such as SAF, DME, Syn-nat gas (SNG), methanol etc can be produced from our syngas and are ideal transition fuels complementary with existing infrastructure networks and applications.

HEAT

A by-product of our process is excess heat that can be used in the pre-drying of feedstock if required or diverted to community heating in cold climate locations. Easily integrated into existing infrastructure and complementary to other renewable energy sources.